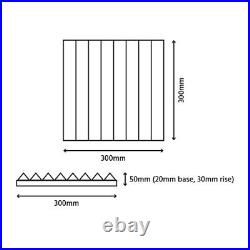

72 x Grey Acoustic Foam Wedge Tiles – 50mm thick 300mm Studio Sound Room Foam. About Acoustic Foam Wedge Tiles. This listing is for – 72 x Grey Acoustic Foam Wedge Tiles – 50mm thick 300mm Studio Sound Room Foam. Just compare our price with competitors. Individual tiles measure 300mm x 300mm and are 50mm thick. Each pack includes 72 acoustic tiles which cover an approximate surface area of 72sqft. Acoustic foam tiles are suitable for balancing mid to high frequency soundwaves. Our thick 50mm tile has a 20mm base and 30mm rise making them super effective for reducing reverberations and echoes within the room. High performance CNC cut, peak wedge profiled, polyurethane acoustic foam tiles in Studio Blue. Suitable for acoustic sound control within recording studios, rehearsal rooms, DJ booths, video workrooms, home cinemas and more. Fully fire retardant – UL94 approved. Exceeds the UK requirements for schedule 1, part 1 the Furniture and Furnishings (fire) (safety) Regulations 1988 (amended 1989). Precision Made in the UK. Combined with our premium high density polyether acoustic grade foam and unique profile shapes we offer the best quality soundproofing online. As UK Foam specialists with over 40 years’ experience we know everything there is about the various grades of foam out there. Our specialist acoustic foam tile grade is manufactured specially to achieve the optimum sound absorption across the entire frequency spectrum. The Best Sound Absorption at A Fraction of the Price. These tiles effectively eliminate any high frequency sound wave incident applied on them by creating several deflection surfaces. When the sound waves hit the peaks and valleys of the foam they get deflected in several directions weakening them. The open cell structure of our specially selected acoustic foam grades then absorbs the sounds. Our precise CNC cut valleys are much greater than that of our competitors which helps to trap air within them forming resonant chambers. These chambers broaden the spectrum of absorption in the medium frequency range. For lower frequency absorption, thicker tiles are required. Very low frequencies for example require super thick blocks of foam to completely absorb the sound incident. However, with correct positioning of our tiles you can greatly reduce the lower frequency distortion. Improving Standards – While Reducing Costs. In simple terms we are able to’cut out the middle man’ to provide direct savings to you. Quality Fire Retardant Foam Made to UK Standards. Our acoustic wedge tiles conform to stringent fire tests and are suitable for studios, cinema rooms or anywhere acoustic control is required. Our acoustic specialist team work to ISO 9001 quality standards to guarantee only the best acoustic foam leaves our foam factory. How Does Acoustic Foam Work? Acoustic foam is primarily designed to treat the acoustics of a room. Although it does have some soundproofing advantages, it is not recommended to be used primarily for soundproofing purposes. Because of its unique structure, acoustic foam works to reduce the energy of sound which is reflected into your ears. These sound reflections can cause distortion and create confusion when mixing and recording. Therefore, it’s important to reduce or eliminate them. Acoustic foam helps to reduce the energy of unnecessary soundwaves and as a result, helps to bring clarity to your recorded sound. Domestically and Commercially Safe – UL94 HF1 Approved. Ensure the safety of you and your valuable recording equipment with GB Foam Direct. These acoustic foam tiles are fire retardant (UL94 HF1 Approved) and exceed the requirements of the Furniture and Furnishings (fire) (safety) Regulations 1988 (amended 1989). Mounting and Placing Your Acoustic Foam. The key to exceptional sound control using acoustic foam tiles is balance. When mounting, carefully consider your placement of them. Try to place them equally across parallel surfaces. We’d also recommend paying close attention to each side of your monitors, as well as behind and in front of them. Make sure to place them in such a way as to achieve the best level of balance possible. Our foam tiles are particularly effective at eliminating unwanted mid to high frequency soundwaves and results are instantaneous. For low frequency soundwaves, please see our full acoustic foam kit which also includes acoustic foam bass traps. Understanding How Sound Works in Your Recording Studio. When purchasing acoustic foam, it’s important to understand the different types of soundwaves that may be present in your recording area. As such, we’ve put together a handy set of diagrams to enable you to understand them better. GB Foam Direct – Sound Guide. By understanding the way in which sound works in your room, you’ll be able to benefit the most from your acoustic foam. The diagrams below outline such topics as reflections, reverberation, direct and indirect sound, flutter echoes and more. Determining Required Frequencies for Treatment. Depending on the type of room you’re working with, you may not need acoustic treatment for a full spectrum of frequencies. If for example, you were to treat a recording studio, it is fair to assume that you would require treatment across a broad range of frequencies. Take something like a lecture room though and you may not need as much acoustic treatment. From this graph, you can see the decibels of a raised tone voice and a normal tone voice in a room. If we analyse the data, it is clear that most of the energy is contained within 300Hz to 1500Hz. A room such as this would benefit most from acoustic treatment which can control frequencies within this range. Sound Waves & Surfaces. Depending on the type of surface a sound wave is striking, it will interact with it in different ways. Acoustic foam, for example, is designed to absorb a portion of sound wave energy. They are also commonly shaped in a way which helps to diffuse the sound wave. The ways in which a sound wave can interact with a surface are as follows – Penetration, Absorption, Reflection and Diffusion. When a sound wave passes through a surface it has penetrated it. If a sound wave dissipates inside a surface it has become absorbed. Reflection is when a sound wave bounces off a surface and travels in a new direction. This can happen multiple times depending on the amount of energy the sound wave contains and the potential for reflection. Diffusion occurs when a sound wave strikes a surface which is not flat. In this instance, the sound wave breaks up into multiple parts and travels in various directions. What is Direct and Indirect Sound? When a sound wave travels straight from the source to your ear, we refer to that sound wave as a direct one. Alternatively, an indirect sound wave is one which ricochets off one or more reflective surfaces before reaching your ear. Ideally, sound should be heard in a direct fashion, however, it is not possible to eliminate all indirect sound waves. Through the use of acoustic treatment though, you can reduce the energy contained within indirect sound waves. This will inhibit their ability to travel to your ears, thus improving the quality of sound. Low Frequencies Vs High Frequencies. Take a look at this diagram. Here you can see the difference between a high-frequency sound wave and a low one (bass). High-frequency sound waves contain more vibrations, which is depicted by multiple inclines and declines. Bass contains less of these but are filled with more energy. The empty space between the incline and decline is a depiction of energy. As you can see, there is much more energy in a low-frequency sound wave. Because of this, thicker pieces of acoustic foam (such as bass traps) are required to contain them. What is a S tanding Wave? A standing wave (otherwise known as a room mode) occurs when a reflected soundwave combines with a direct soundwave. This tends to occur when one or more of the rooms dimensions is a direct multiple of a sounds wavelength. If two waves are of the same frequency they are said to be in-phase. The result, we will hear both waves at the same frequency, but as they are combined they will have a higher amplitude. The Quarter Wavelength Rule. This is an effective method for better determining the optimal placement of acoustic treatment. The quarter wavelength rule is a popular method applied to work out the quarter point of a sound wave. By acoustically treating areas at this point, you can maximise the efficiency of your acoustic treatment. Remember that this calculation helps to determine the quarter wavelength of a certain frequency. If you wish to treat multiple frequencies, thicker acoustic material will be needed. Calculating the length of a sound wave is simple. All you need to do is divide the speed of sound (approximately 1132 ft per second) by the hertz of the sound. As an example, to calculate the wavelength of 60Hz you would divide 1132 by 60. This would give you 18. Thus, you can summarise that the wavelength is approximately 18-foot-long. Divide this length by 4 to determine the quarter wavelength measurement. What are Primary Reflections? Primary reflections are sound waves which ricochet off one reflective surface before reaching your ears. If your room is not properly treated with acoustic foam, you are likely to experience significant sound interference. This is because these early reflections still contain large amounts of energy. Our acoustic foam helps to soften vulnerable surfaces and reduce the energy contained within the sound wave. What are Early Reflections and Reverberation? In a smaller confined room, reflections are usually so close together that we cannot perceive them individually; we call these early reflections. The effect because of this is commonly referred to as reverberation or “reverb” for short. Even in larger recording rooms however, this effect can still take place. Eventually sound reflections will evolve into reverb as they become increasingly more complex. What are Flutter Echoes? When sound waves continuously bounce between two solid parallel surfaces, a flutter echo is created. Depending on the space between each parallel surface, the flutter echoes can be either interpreted as a continuing echo or in quick succession. By softening at least one of the parallel surfaces at risk of creating a flutter echo, you can prevent them from occurring. The best way to do this is by mounting acoustic foam to this surface. Did you know that the position of your monitors can affect the quality of your sound? Ideally, you should be stationed in the center of your room. Your monitors should be placed equidistant on either side of you. They should also be angled inwards towards you at a 60-degree angle. This helps to ensure that your monitors project sound waves which travel directly to your eardrums. Why Use Acoustic Tiles? We can utilise the properties of acoustic foam to absorb great deals of energy at reflection points. In this diagram, you can see how the energy of a primary reflection is reduced when using a acoustic foam tile. The left ear receives much more energy than the right ear does. Why Use Bass Traps? Low frequencies or bass contain much more energy than mid to high frequency sound waves. As such, thicker acoustic foam is required to absorb low frequency energy. Bass traps are an ideal way of managing unwanted low frequency sound waves which cause sound interference. Bass is much more likely to become trapped in room corners and reflect between the surfaces. Our precision engineered bass traps prevent this. How Acoustic Foam is Made. Like many other types of foam you may be familiar with, acoustic foam is a polyurethane foam. These types of foam are usually made from 50% polyol, 40% polyisocyanates and 10% water/other chemicals. All these chemicals are reactive to each other. As such, they must be blended together inside a mixing head. This is what helps to kickstart the foaming process. Once the chemicals have been mixed together, they are poured onto a conveyer belt. This conveyer belt moves at a slow speed. As the mixture moves along the conveyer belt, it begins to rise forming a long block of foam. At this stage, the foam is referred to as slabstock. The slabstock continues to move slowly along the conveyer belt, still rising as time passes. Eventually, it meets a horizontal bandsaw which cuts the slabstock into smaller more manageable blocks of polyurethane foam. From here, these blocks are unloaded and left to cure for around 12 hours. Once the foam blocks have had enough time to cure they can be sent for conversion. Here the foam is cut using specialist equipment. It is made into a variety of acoustic treatment products which you can use in your home or place of work. About GB Foam Direct. Our factory is equipped with the latest CNC cutting technology and throughout the years we have employed the most talented freehand foam cutters in the industry. Many members of the team have worked for the company for several decades and their attention to detail and quality control is something that only comes with years of knowledge and experience. We have many customers who started with us in 1976 and are still working with us today, which we like to think reflects on our vision to be the most dynamic foam converter in our industry. For us no job is too big or too small. This item is in the category “Musical Instruments & DJ Equipment\Pro Audio Equipment\Acoustic Treatments”. The seller is “gbfoamdirect” and is located in this country: GB. This item can be shipped to United Kingdom, Antigua and Barbuda, Austria, Belgium, Bulgaria, Republic of Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Australia, United States, Bahrain, Canada, Brazil, Japan, New Zealand, China, Israel, Hong Kong, Norway, Indonesia, Malaysia, Mexico, Singapore, South Korea, Switzerland, Taiwan, Thailand, Bangladesh, Belize, Bermuda, Bolivia, Barbados, Brunei Darussalam, Cayman Islands, Dominica, Ecuador, Egypt, Guernsey, Gibraltar, Guadeloupe, Grenada, French Guiana, Iceland, Jersey, Jordan, Cambodia, Saint Kitts-Nevis, Saint Lucia, Liechtenstein, Sri Lanka, Macau, Monaco, Maldives, Montserrat, Martinique, Nicaragua, Oman, Pakistan, Peru, Paraguay, Reunion, Turks and Caicos Islands, Aruba, Saudi Arabia, South Africa, United Arab Emirates, Chile, Bahamas, Colombia, Costa Rica, Dominican Republic, Guatemala, Honduras, Jamaica, Kuwait, Panama, Philippines, Qatar, El Salvador, Trinidad and Tobago, Vietnam.

- Colour: Grey

- Country/Region of Manufacture: United Kingdom

- Item Width: 300mm

- Material: Foam

- Compatible Installation Surface: Drywall, Wood

- Type: Acoustic Foam

- Number in Pack: 72

- Features: High Density

- Item Thickness: 50mm

- Item Length: 300mm

- Quantity: Pack of 72 Tiles

- Dimensions: 300 x 300 x 50mm Tile

- Packaging: Box

- Brand: GB Foam Direct

- Suitable For: Booth, Ceiling, Interior Wall, Room